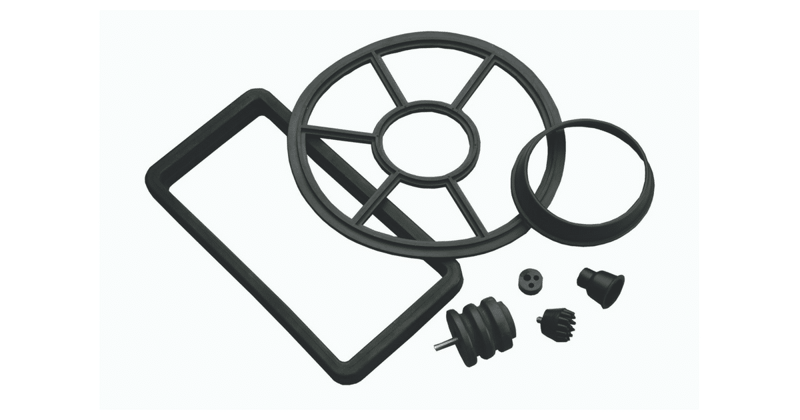

Custom Molded Rubber

Custom molded silicone and rubber made to your exact specifications.

We strive to respond to all quotes within 24 hours or less

We specialize in:

- Custom molded rubber parts

- Production facilities in both the USA and China

- Prototype and production volumes

- Small parts as well as larger or more complex shapes

A Few of Our Partners

-1.png)

Common APPLICATIONS

Our Experience

Materials

We can manufacture custom molded parts out of Silicone Molding Compounds, Rubber Molding Compounds, as well as Class 3B Silicone.

How Flory Industries Simplifies Procurement

Learn more about how Flory Industries builds strategic supplier relationships for sourcing materials and parts.

Read the Case Study

How Does Our Process Work?

We pride ourselves on being your obvious choice as a manufacturing partner through the entire product lifecycle. We can help with the prototype to production volumes, and work with you to reduce costs and lead times along the way.

Frequently Asked Questions

There are many different molding techniques, but compression molding is probably the most commonly used method (and our method of choice) for molding a custom gasket. Compression molding is a production process that uses heat and pressure to shape a pliable raw material into a finished product.

Typically, the mold is made of steel or aluminum and contains machined cavities. The uncured silicone or raw material is inserted in the mold cavities in a putty-like state, and after 7-10 minutes cures to a finished rubber like material. The shape and size of the molding cavity determines the final form of the gasket material. Compression molding supports the manufacture of small parts as well as larger gaskets in addition to accommodating precise gasket details for intricate and complex gasket designs.

There are many occasions in which a local home improvement store or industrial distributor doesn’t stock the exact part required. OEMs and any businesses that use heavy equipment or precision machinery will need custom solutions at some point. This ensures optimal use, personnel protection, and extended life for valuable assets. Where on-shelf options fail, custom solutions can provide tailor-made materials that fit your exact specifications.

This guide will provide basic info for the manufacturing methods, material types and properties of custom rubber parts.

More Information About Custom Molded Rubber

Learn more about custom gasket production with resources from our learning center.

3D Printing vs. Compression Molding: What’s the Right Choice?

The Best Manufacturing Method To Prototype Custom Molded Rubber Parts

Speak to an ENGINEER today.

We strive to get every quote turned around in 24 hours or less to make sure you get the information you need faster.